Instrument rests, swab and pipette holders, component nests with solvent‑resistant polymers.

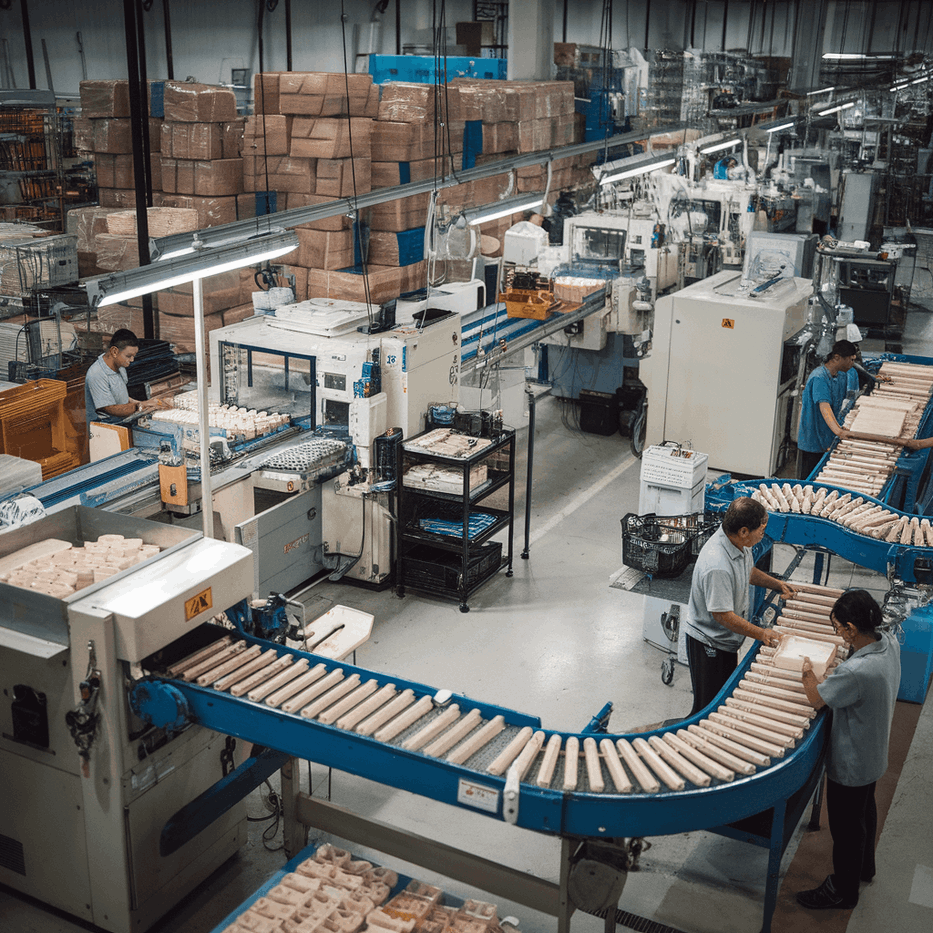

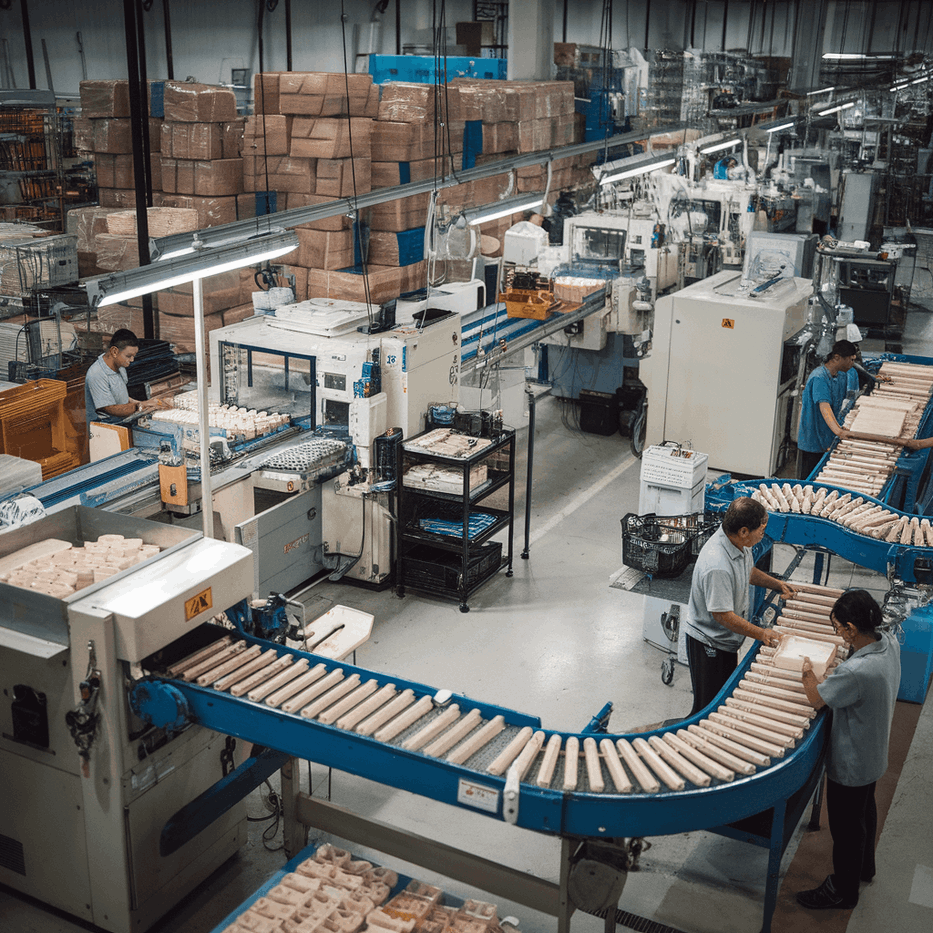

We injection‑mould and assemble disposable holders, protective cases, and procedure accessories for hospitals and OEMs. Our cleanroom cells in Shah Alam deliver repeatable quality, at scale.

CNBP Plastics is a focused manufacturing partner for disposable medical plastic components. Founded and operated in Shah Alam, we combine precise tooling, process discipline, and responsive program management to help OEMs launch and sustain regulated products.

From tool steel to labeled cartons, our vertically integrated teams handle every detail.

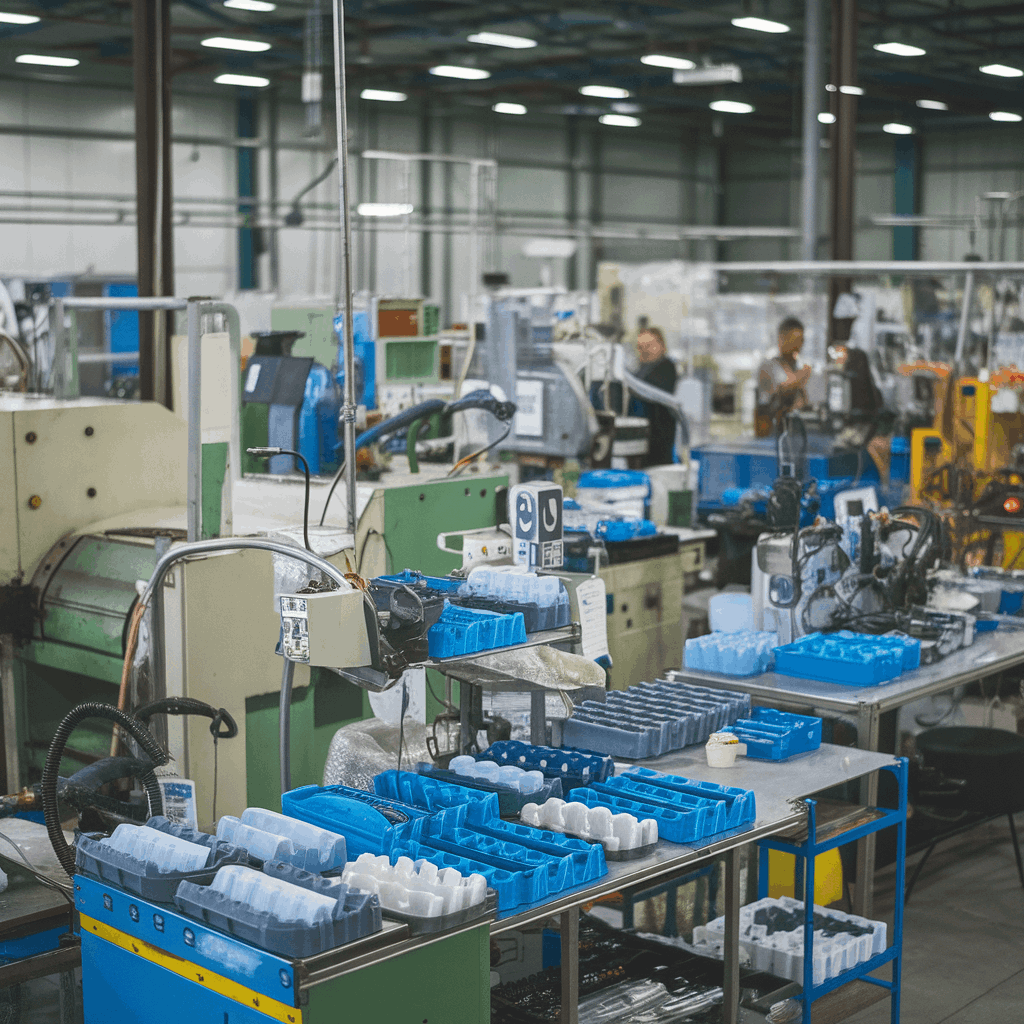

24–220T presses with scientific moulding, hot runners, and cavity pressure monitoring.

ISO Class 8 rooms for kitting, ultrasonic welding, adhesive bonding, and inspection.

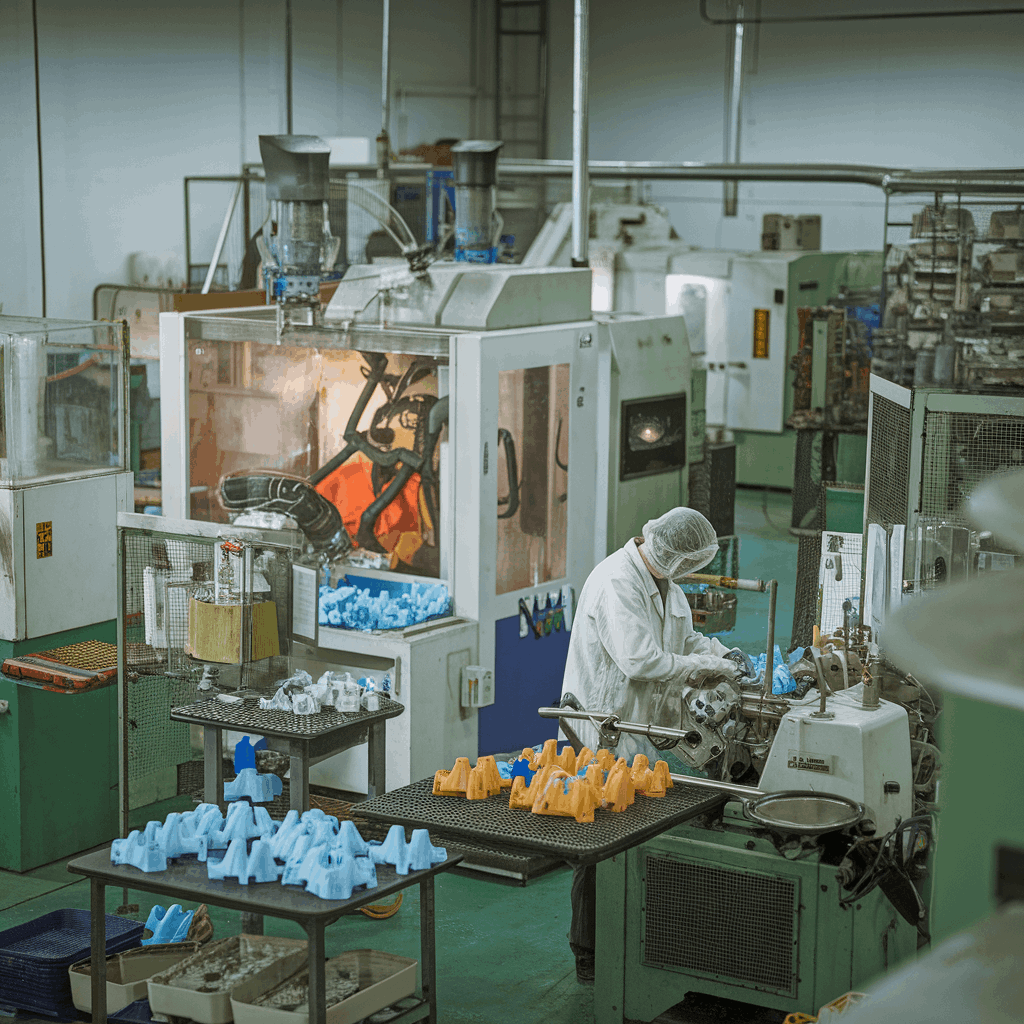

QMS aligned to ISO 13485 with risk-based validation, PPAP, and lot genealogy.

Common families we supply. We also support custom geometries and colors.

Instrument rests, swab and pipette holders, component nests with solvent‑resistant polymers.

Rigid and hinged cases for vials and kits; optional tamper‑evident snap features.

Caps, tips, spacers and custom accessories for procedure packs and hospital logistics.

We validate processes with IQ/OQ/PQ protocols and monitor critical parameters on every lot. Our eDHR system ties operators, stations, tools, and materials together so issues are traceable and contained.

External reference: Medical Device Authority (Malaysia)

We reduce resin waste, optimise cycle times, and design parts that ship efficiently.

We review CAD, propose gate/parting, and confirm tooling approach with a clear schedule.

First article inspections with dimensional reports and resin certs; iterate for fit & function.

Run IQ/OQ/PQ, document parameters and acceptance criteria, then lock the process window.

Visit us in Shah Alam, Selangor, or send your RFQ package. We typically respond in under one business day.

Lot 22, Jalan Teknologi 3/7, Kota Damansara,

Shah Alam, Selangor, Malaysia

+60 3-5612 4490 • contact@bookofcnbp.org